AHU Cleaning Chemical

Product Details:

- Appearance Clear liquid

- Grade Industrial Grade

- Ph Level 11 (Alkaline)

- Other Names Air Handling Unit Coil Cleaner, AHU Coil Cleaner

- Usage Dilute with water as per instructions before use

- Density 1.04 Gram per cubic centimeter(g/cm3)

- Solubility Completely soluble in water

- Click to View more

AHU Cleaning Chemical Price And Quantity

- 90 INR/Kilograms

- 100 Kilograms

AHU Cleaning Chemical Product Specifications

- Store in a cool, dry and well-ventilated place, away from sunlight

- 340290

- 11 (Alkaline)

- Air Handling Unit Coil Cleaner, AHU Coil Cleaner

- Dilute with water as per instructions before use

- Industrial Grade

- Clear liquid

- Completely soluble in water

- 99%

- 1.04 Gram per cubic centimeter(g/cm3)

- Mild

- Cleaning AHU, HVAC coils and fins

- NO

- 2 years

- Liquid

- AHU Cleaning Chemical

- Liquid

AHU Cleaning Chemical Trade Information

- 1000 Kilograms Per Week

- 2 Week

Product Description

AHU Cleaning Chemical

BASIC CHARACTERISTICS:

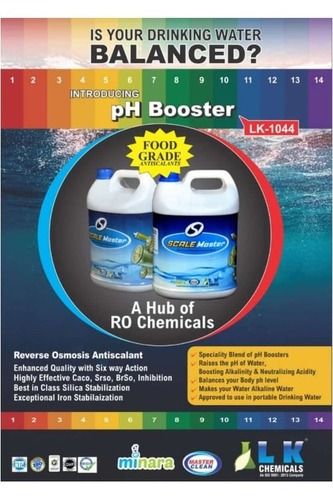

LK 2011 is custom made pH booster to maintain the right level of pH and Alkalinity in feed and product water

Function & Feature

LK 2011 maintains boiler feed water pH and the correct level of Hydroxyl Alkalinity in order to protect the Boiler internals from water side problems

Product Properties

Form : Liquid

Colour : Pale Yellow

pH : 12.0 13.0

Specific Gravity :10.8 +/- 0.5

Solubility in water: Highly Soluble

Dosage

LK 2011 is found to be effective in the dose range of 15 to 20 ppm based on total hardness in feed. However, the system specific dose shall be recommended by our technical representatives

HANDLING AND SAFETY

LK 2011 should be handled like any other industrial product like acid, alkali etc., Safety gears such as safety shoes, gloves and goggles should be worn, while handling the product. In case of accidental contact with skin or any other part, the affected area should be washed with plenty of fresh water and immediate medical assistance should be taken. The product has no environmental hazard and water treated with the product can be safely discharged into any waste stream, without need for post treatment

SHIPPING

LK 2011 is shipped from manufacturing and regional distribution centers in 55/200 Kg HMHDPE drums

Please contact for further details.

Advanced Foaming Formula for Effective Coil Cleaning

With heavy foaming action, our AHU Cleaning Chemical penetrates deep into coils and fins, dislodging dirt, grime, and biological residues. This enhances heat exchange efficiency and airflow, resulting in optimal system performance and energy savings. Its non-corrosive and non-toxic properties ensure safe and reliable cleaning on all compatible metals.

Safety, Compatibility, and Eco-Friendliness Combined

Formulated with user and environmental safety in mind, the product is non-flammable, non-poisonous, and leaves no harmful residues. It is compatible with aluminum, copper, and steel coils, making it versatile for various industrial HVAC systems. Being readily biodegradable and eco-friendly, it supports responsible facility management.

FAQs of AHU Cleaning Chemical:

Q: How is the AHU Cleaning Chemical used for cleaning coils?

A: To use the AHU Cleaning Chemical, dilute it with water as per instructions. Apply the solution evenly over the coil surfaces, allow adequate contact time for deep cleaning, and then rinse thoroughly with water. Always wear gloves and eye protection during use.Q: What are the key benefits of using this AHU Cleaning Chemical?

A: This cleaner delivers heavy foaming for deep coil cleaning, is non-corrosive to metals, non-toxic, and leaves no harmful residue. Its biodegradability makes it eco-friendly, while being shelf-stable guarantees long-term usability.Q: When should I apply the AHU Cleaning Chemical for optimal results?

A: It is best to clean AHU and HVAC coils during routine system maintenance or whenever a buildup of dust and debris is observed. Regular use ensures efficient airflow and prolongs the lifespan of your HVAC units.Q: Where can this cleaner be applied?

A: This product is suitable for use on aluminum, copper, and steel coils or fins in air handling units and various HVAC systems for industrial or commercial environments.Q: What process should be followed to ensure safe and effective cleaning?

A: Dilute the chemical as per instructions, apply on surfaces with heavy foaming action, allow sufficient contact time for deep cleaning, rinse thoroughly with water, and avoid direct contact with skin or eyes by wearing appropriate PPE.Q: Is the AHU Cleaning Chemical safe for both users and the environment?

A: Yes, it is designed to be non-toxic, non-poisonous, and non-flammable. When used as directed, it is safe for personnel and, being readily biodegradable, it poses minimal environmental impact.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

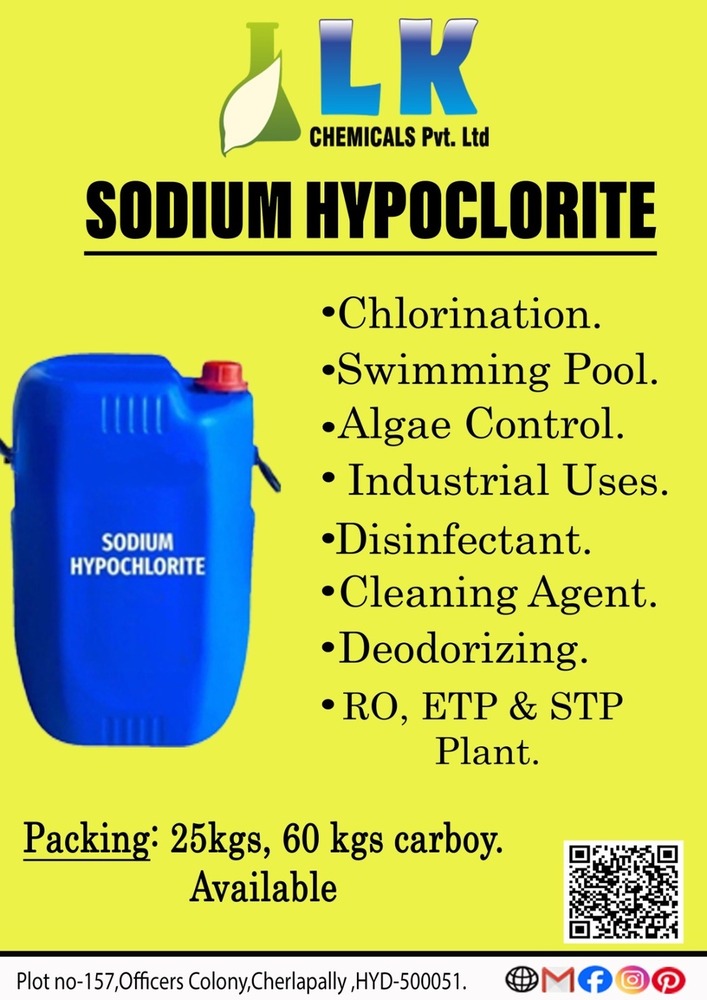

Other Products in 'Cleaning Chemicals' category

|

L K CHEMICALS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free